Publications

Patents and Disclosures

- R. Pitchumani and S.K. Purayil, Fractal Textured High Efficiency Solar Absorber Coatings, U.S. Provisional Patent No. 63/329,842, PCT/US2023/018223; U.S. Patent 18/856,122 (Pending).

- R. Pitchumani and R. Stoddard, Solid-infused surfaces, articles incorporating solid-infused surfaces, methods of making, and methods of use thereof, U.S. Provisional Patent No. 63/185,973, PCT/US2022/028232; U.S. Patent 18/559,525 (Pending).

- R. Pitchumani, A. Haghdoost and M. Kargar, Fabricating Porous Metallic Coatings Via Electrodeposition And Compositions Thereof, U.S. Patent 17/347,508 (Pending).

- R. Pitchumani and A. Donato, Tunable Swing Adsorption Separation Process, VTIP 12-155, Intellectual Property Disclosure (2012).

Publications

A. Book Chapters

- Processing of Thermoplastic Composites, Chapter 4 in Annual Review of Heat Transfer, C. L. Tien, V. Prasad, and F. P. Incropera, eds., Vol. XII, pp. 117–186, Begell House, 2002 (ISBN: 1-56700-166-1)

- Transport Phenomena in Materials Processing, Chapter 17 in Heat Transfer Handbook, (with R.N. Smith and C. Doumanidis), A. Bejan & A. Kraus, eds., pp. 1231–1307, Wiley, 2003 (ISBN: 978-0-471-39015-2)

- Design of a Fusion Bonding Process for Fabricating Thermoplastic-Matrix Composites, Chapter 42 in Handbook of Heat Transfer Calculations, Myer Kutz, ed., pp. 42.1–42.22, McGraw Hill, 2005 (ISBN: 0-07141-041-4)

- Transport and Electrochemical Phenomena, Chapter 4 in Fuel Cell Technology: Reaching Towards Commercialization (with F. Yang), N. Sammes, ed., pp. 69–163, Engineering Materials and Processes Series, Derby, Series ed., Springer-Verlag, 2006 (ISBN: 1-85233-974-8)

- Computational Methods in Materials Processing, Chapter 24 in Handbook of Numerical Heat Transfer, Second Edition, W. Minkowycz, E. Sparrow, and J. Murthy, eds., pp. 785–819, Wiley, 2006 (ISBN: 0-471-34878-3)

- Interphases in Composites, Chapter 3 in Long-Term Durability of Polymeric Matrix Composites, 1st Edn, K.V. Pochiraju, G.P. Tandon, and G.A. Schoeppner, eds., pp. 77–120, Springer, 2012 (ISBN: 978-1-4419-9308-3).

- High Temperature Latent Heat Storage for Concentrating Solar Thermal (CST) Systems, Chapter 10 in Advances in Concentrating Solar Thermal Research and Technology, (with J. Stekli and K. Nithyanandam), M. Blanco, ed., pp. 213–246, 2017 (ISBN: 978-0-0810-0516-3).

- Thermochemical Energy Storage for Concentrating Solar Thermal (CST) Systems, Chapter 11 in Advances in Concentrating Solar Thermal Research and Technology, (with J. Stekli, L. Irwin and C. Pfefferkorn), M. Blanco, ed., pp. 247–267, 2017 (ISBN: 978-0-0810-0516-3).

- Solid Particle Thermal Energy Storage for High-Temperature CSP Applications, Chapter 13 in Thermal Energy, (with K. Kant), A. Shukhla, A. Sharma, and K. Kant, eds., pp. 262–274, CRC Press, Boca Raton, FL, 2023 (ISBN: 9781003345558).

B. Edited Volumes

- Thermal Processing of Materials: Thermomechanics, Controls, and Composites, (with V. Prasad et al.) Vol. HTD-289, ASME Press, New York 1994.

- Physical Properties of Composites, (with P.K. Liaw), ISBN: 0-87339-329-5, TMS Press, 1996

- Transport Phenomena in Materials Processing and Manufacturing, (with T. L. Bergman, et al.) Vol. HTD-347, ASME Press, New York, 1997.

- Heat Transfer in Materials Processing, (with U. Chandra, et al.), Vol. HTD-361-4, ASME Press, New York, 1998.

- Advances in Sensing and Control for Thermal Processing in Manufacturing, ASME-HTD CD Volume 0-7918-1997-3, 1463CD, National Heat Transfer Conference Proceedings, 2000.

- Proceedings of the ASME Heat Transfer Division—2000, with J. H. Kim, et al., Vol. HTD-366-3, ISBN: 0-7918-1908-6, ASME Press, New York, 2000.

- Proceedings of the Symposium on Polymer and Composite Materials Processing, with S.G. Advani and S.T. Holmes, CD-ROM Volume, ASME Press, New York, 2001 (November 2001)

- Proceedings of the SolarPACES 2013 International Conference, R. Pitchumani, ed., Energy Procedia, Open Access Edited Volume, Elsevier, 2014 (262 articles; 2,520 pages).

- Progress in Solar Energy, Special Issue: Advances in Concentrating Solar Power, R. Pitchumani, ed., Solar Energy, Volume 152, 207 pp., Elsevier, 2017.

C. Refereed Journal Articles

- J.I. Ramos and R. Pitchumani, “An analysis of laminar boundary layers on liquid curtains,” Journal of Appl. Mathematics and Physics, 40, 721–739, 1989.

- J.I. Ramos and R. Pitchumani, “Liquid Curtains–II. Gas Absorption,” Chemical Engineering Science, 45(6), 1595–604, 1990.

- J.I. Ramos and R. Pitchumani, “Dynamics of liquid membranes. I. Non–adaptive finite difference methods,” International Journal for Numerical Methods in Fluids, 12(9), 859–879, 1991.

- R. Pitchumani and S.C. Yao, “Correlation of Thermal Conductivities of Unidirectional Fibrous Composites Using Local Fractal Techniques,” ASME Journal of Heat Transfer, 113(4), 788–796, 1991.

- R. Pitchumani and S.C. Yao, “Evaluation of Transverse Thermal Diffusivities of Fiber–reinforced Composites,” International Journal of Heat and Mass Transfer, 35(9), 2185–2194, 1992.

- P.K. Liaw, R. Pitchumani, and D.K. Hsu, “Eddy Current Characterization of Silicon Carbide Reinforced Aluminum Metal–matrix Composites,” in Advances in Damage of Composite Materials, G. Z. Voyiadjis ed., Elsevier Science Publishers B.V., The Netherlands, 249–282, 1992.

- R. Pitchumani and S.C. Yao, “Non–dimensional Analysis of Thermoset Composites Manufacture,” Journal of Composite Materials, 27(6), 613–636, 1993.

- A. K. Kordon, R. Pitchumani, A. N. Beris, V. Karbhari, “A Rheological Model for Particulate Ceramic Slurries at Low Temperatures,” Scripta Metallurgica et Materialia, 29(8), 1095–1099, 1993.

- R. Pitchumani, P. A. Schwenk, and V. M. Karbhari, “Knowledge–based Expert Systems for Composites Manufacturing,” Ceramic Bulletin, 142(3), 53–57, 1994.

- P. K. Liaw, R. Pitchumani, D. K. Hsu, H. Jeong, and S. C. Yao “Nondestructive evaluation of anisotropic conductivities of SiCp/Al composite extrusions,” Trans. ASME, Journal of Engineering for Gas Turbines and Power, 116(3), 647–656, 1994.

- R. Pitchumani, P. K. Liaw, D. K. Hsu, and S. C. Yao, “An Eddy Current Technique for the Measurement of Constituent Volume Fractions in a Three–Phase Metal–Matrix Composite,” J. Composite Materials, 28(18), 1742–1769, 1994.

- R. Pitchumani, A. K. Kordon, A. N. Beris, B. R. Rossing, and W. B. Johnson “Thermofluid Analysis and Design of a Low Temperature Ceramic Injection Molding Process,” Metallurgical and Materials Transactions B, 25B, pp. 761–771, 1994.

- R. Pitchumani, P. A. Schwenk, V. M. Karbhari, J. F. Ramsay, and T. D. Claar, “An Expert System Approach to Manufacturing Preforms for Infiltration–Processing of Ceramic and Metal Matrix Composites,” Processing of Advanced Materials, 9, pp. 155–165, 1994.

- R. Pitchumani, P. K. Liaw, S. C. Yao, H. Jeong, and D. K. Hsu, “Theoretical Models for the Anisotropic Conductivities of Two–phase and Three–phase Metal–Matrix Composites,” Acta Metallurgica et Materialia, 43(8), pp. 3045–3059, 1995.

- R. Pitchumani and V.M. Karbhari “A Generalized Fluid Flow Model for Ceramic Tape Casting,” Journal of the American Ceramic Society, 78(9), pp. 2497–2503, 1995.

- R. Pitchumani, S. Ranganathan, R.C. Don, J.W. Gillespie, Jr., and M.A. Lamontia, “Analysis of Transport Phenomena Governing Interfacial Bonding and Void Dynamics During Thermoplastic Tow-Placement,” International Journal of Heat and Mass Transfer, 39(9), pp. 1883–1897, 1996.

- R. Pitchumani, J.W. Gillespie, Jr. and M.A. Lamontia, “Design and Optimization of a Thermoplastic Tow-Placement Process,” Journal of Composite Materials, 31(3), pp. 244–275, 1997.

- N. Rai and R. Pitchumani, “Optimal Cure Cycles for the Fabrication of Thermosetting-matrix Composites,” Polymer Composites, 18(4), pp. 566–581, 1997.

- N. Rai and R. Pitchumani, “Rapid Cure Simulation Using Artificial Neural Networks,” Composites A: Applied Science and Manufacturing, 28A, pp. 847–859, 1997.

- D. Sadagopan and R. Pitchumani, “A Combinatorial Optimization Approach to Composite Materials Tailoring,” ASME Journal of Mechanical Design, 119(4), pp. 494–503, 1997.

- N. Rai and R. Pitchumani, “Neural Network-based Optimal Curing of Composite Materials,” Journal of Materials Processing and Manufacturing Science, 6(1), pp. 39–62, 1997.

- D. Sadagopan and R. Pitchumani, “Application of Genetic Algorithms to Optimal Tailoring of Composite Materials,” Composites Science and Technology, 58(3–4), pp. 571–589, 1998.

- C. A. Butler, R. L. McCullough, R. Pitchumani, J. W. Gillespie, Jr., and A. R. Wedgewood “An Analysis of Mechanisms Governing Fusion Bonding of Thermoplastic Composites,” Journal of Thermoplastic Composite Materials, 11(4), pp. 338–363, 1998.

- D. Sadagopan and R. Pitchumani, “Property-based Optimal Design of Composite Materials and their Internal Architectures,” Journal of Composite Materials, 32(19), pp. 1714–1752, 1998.

- S.K. Padmanabhan and R. Pitchumani, “Stochastic Analysis of Isothermal Cure of Resin Systems,” Polymer Composites, 20(1), 72–85, 1999.

- B. Ramakrishnan and R. Pitchumani, “A Fractal Geometry Model for Evaluating Permeabilities of Porous Preforms Used in Liquid Composite Molding,” International Journal of Heat and Mass Transfer, 42(12), 2219–32, 1999.

- R. Pitchumani, “Evaluation of Thermal Conductivities of Disordered Composite Media Using a Fractal Model,” ASME Journal of Heat Transfer, 121(1), pp. 163–166, 1999.

- S.K. Padmanabhan and R. Pitchumani, “Stochastic Modeling of Nonisothermal Flow During Resin Transfer Molding Processes,” International J. Heat and Mass Transfer, 42(16), 3057–70, 1999.

- L. Zhu and R. Pitchumani, “Processing Envelopes for Supplemental Internal Resistive Heating During Composites Cure,” Journal of Reinforced Plastics and Composites, 18(13), 1242–1253, 1999.

- B. Ramakrishnan, L. Zhu, and R. Pitchumani, “Curing of Composites Using Internal Resistive Heating,” ASME Journal of Manufacturing Science and Engineering, 122(1), 124–131, 2000.

- B. Ramakrishnan and R. Pitchumani, “Fractal Permeation Characteristics of Preforms Used in Liquid Composite Molding,” Polymer Composites, 21(2), 281–296, 2000.

- L. Zhu and R. Pitchumani, “Analysis of a Process for Curing Composites by the Use of Embedded Resistive Heating Elements,” Composites Science & Technology, 60, 2699–2712, 2000.

- F. Yang and R. Pitchumani, “Fractal Description of Interlaminar Contact Development During Thermoplastic Composites Processing,” J. Reinforced Plastics & Composites, 20(7), 536–546, 2001.

- D. Nielsen and R. Pitchumani, “Intelligent Model-based Control of Preform Permeation in Liquid Composite Molding Processes, with Online Optimization,” Composites A: Applied Science & Manufacturing, 32(12), 1789–1803, 2001.

- F. Yang and R. Pitchumani, “A Fractal Cantor Set-based Description of Intimate Contact Evolution During Thermoplastic Composites Processing,” Journal of Materials Science, 36(19), 4661–4671, 2001.

- D. Nielsen and R. Pitchumani, “Closed-loop Flow Control in Resin Transfer Molding Using Real-Time Numerical Process Simulations,” Composites Science and Technology, 62, 283–298, 2002.

- F. Yang and R. Pitchumani, “Interlaminar Contact Development in Thermoplastic Fusion Bonding,” Polymer Engineering and Science, 42(2), 424–438, 2002.

- F. Yang and R. Pitchumani, “Healing of Thermoplastic Polymers at an Interface Under Nonisothermal Conditions,” Macromolecules, 35(8), 3213–3224, 2002.

- D. Nielsen and R. Pitchumani, “Control of Flow in Resin Transfer Molding with Real-time Preform Permeability Estimation,” Polymer Composites, 23(6), 1087–1110, 2002.

- F. Yang and R. Pitchumani, “Nonisothermal Healing and Interlaminar Bond Strength Evolution During Thermoplastic Matrix Composites Processing,” Polymer Composites, 24(2), 262–278, 2003.

- X. Guan and R. Pitchumani, “Viscous Fingering in a Hele-Shaw Cell with Finite Viscosity Ratio,” ASME Journal of Fluids Engineering, 125(2), 354–364, 2003.

- A. Mawardi and R. Pitchumani, “Optimal Temperature and Current Cycles for Accelerated Curing of Composites Using Internal Resistive Heating,” ASME Journal of Heat Transfer, 125(1), 126–136, 2003.

- F. Yang and R. Pitchumani, “A Kinetics Model for Interphase Formation in Thermosetting-Matrix Composites,” Journal of Applied Polymer Science, 89(12), pp. 3220–3236, 2003.

- R.J. Johnson and R. Pitchumani, “Enhancement of Resin Flow in VARTM Using Induction Heating,” Composites Science and Technology, 63, pp. 2201–2215, 2003.

- X. Guan and R. Pitchumani, “Modeling of Spherulitic Crystallization in Thermoplastic Tow-Placement Process: Heat Transfer Analysis,” Composites Science and Technology, 64(9), pp. 1123–1134, 2004.

- X. Guan and R. Pitchumani, “Modeling of Spherulitic Crystallization in Thermoplastic Tow-Placement Process: Spherulitic Microstructure Evolution,” Composites Science and Technology, 64(9), pp. 1363–1374, 2004.

- X. Guan and R. Pitchumani, “A Micromechanical Model for the Elastic Properties of Semicrystalline Thermoplastic Polymers,” Polymer Engineering and Science, 44(3), pp. 433–51, 2004.

- F. Yang and R. Pitchumani, “Effects of Interphase Formation on the Modulus and Strength of Fiber-reinforced Thermosetting-matrix Composites,” Composites Science and Technology, 64(10–11), pp. 1437–1452, 2004.

- A. Mawardi and R. Pitchumani, “Cure Temperature Cycle Design for Composites Fabrication Under Uncertainty,” Annals of Operations Research, 132, 19–45, 2004.

- V. Mishra, F. Yang, and R. Pitchumani, “Measurement and Prediction of Electrical Contact Resistance between Gas Diffusion Layers and Bipolar Plate for Applications to PEM Fuel Cells,” ASME Journal of Fuel Cell Science and Technology, 1(1), 2–9, 2004.

- A. Mawardi and R. Pitchumani, “Design of Microresonators under Uncertainty,” Journal of Microelectromechanical Systems, 14(1), 63–69, 2005.

- F. Yang and R. Pitchumani, “An Analytical Solution for Thermal Transport in Deep X-ray Lithography,” Journal of Micromechanics and Microengineering, 15, 474–484, 2005.

- A. Mawardi and R. Pitchumani, “SAMS: Stochastic Analysis with Minimal Sampling—A Fast Algorithm for Analysis and Design Under Uncertainty,” ASME Journal of Mechanical Design, 127(4), 558–571, 2005.

- V. Mishra, F. Yang, and R. Pitchumani, “Analysis and Design of PEM Fuel Cells,” Journal of Power Sources, 141(1), 47–64, 2005.

- A.M. Morales, R. Pitchumani, T.J. Garino, A.K. Gutmann, and L.A. Domeier, “Fabrication of Ceramic Microstructures via Microcasting of Nanoparticulate Slurry,” Journal of the American Ceramic Society, 88(3), 570–578, 2005.

- F. Yang and R. Pitchumani, “Processing-Interphase-Property Relationships in Fiber-reinforced Thermosetting-matrix Composites,” Polymer Composites, 26(2), 193–208, 2005.

- Q. Jiang, F. Yang, and R. Pitchumani, “Coating Thickness Variations in Optical Fiber Drawing Process,” Journal of Lightwave Technology, 23(3), 1261–1272, 2005.

- A. Mawardi, F. Yang, and R. Pitchumani, “Optimization of the Operating Parameters of a Proton Exchange Membrane Fuel Cell for Maximum Power Density,” ASME Journal of Fuel Cell Science and Technology, 2(2), 121–135, 2005.

- A. Mawardi and R. Pitchumani, “Design of a Micromachined Force Gauge under Uncertainty,” Journal of Micromechanics and Microengineering, 15, 2353–2365, 2005.

- F. Zhang, A. Mawardi, E. Santos, Jr., R. Pitchumani, and L.E.K. Achenie, “Examination of Load-Balancing Methods to Improve Efficiency of a Composite Materials Manufacturing Process Simulation Under Uncertainty using Distributed Computing,” Future Generation Computer Systems, 22(5), 571–587, 2006.

- C. Acquah, I. Datskov, A. Mawardi, F. Zhang, L.E.K. Achenie, R. Pitchumani, E. Santos, Jr., “Simulation and Analysis of a Composite Fabrication Process using a Critical Point Model and a Sampling-based Model,” Computers and Chemical Engineering, 30(6–7), 947–960, 2006.

- Y. Xiao, F. Yang, and R. Pitchumani, “A Generalized Analysis of Capillary Flows in Channels,” J. Colloid and Interface Science, 298(2), 880–888, 2006.

- Y. Yan and R. Pitchumani, “Numerical Study on the Dopant Concentration and Refractive Index Profile Evaluation in an Optical Fiber Manufacturing Process,” Int. Journal of Heat & Mass Transfer, 49(13–14), 2097–2112, 2006.

- A. Mawardi and R. Pitchumani, “Effects of Parameter Uncertainty on the Performance Variability of Polymer Electrolyte Membrane Fuel Cells,” Journal of Power Sources, 160(1), 232–245, 2006.

- C. Acquah, I. Datskov, A. Mawardi, F. Zhang, L.E.K. Achenie, R. Pitchumani, and E. Santos, Jr., “Optimization of an Optical Fiber Drawing Process Under Uncertainty,” Industrial and Engineering Chemistry Research, 45(26), 8475–8483, 2006.

- R.J. Johnson and R. Pitchumani, “Simulation of Active Flow Control based on Localized Preform Heating in a VARTM Process,” Composites A: Applied Sci. and Manufacturing, 37(10), 1815–30, 2006.

- Y. Zhang, A. Mawardi, and R. Pitchumani, “Effects of Operating Parameters on the Uniformity of Current Density Distribution in Polymer Electrolyte Membrane Fuel Cells,” ASME Journal of Fuel Cell Science and Technology, 3(4), 464–476, 2006.

- R.J. Johnson and R. Pitchumani, “Flow Control Using Localized Induction Heating in a VARTM Process,” Composites Science & Technology, 67(3–4), 669–684, 2007.

- Y. Zhang and R. Pitchumani, “Numerical Studies on an Air-breathing Proton Exchange Membrane (PEM) Fuel Cell,” International Journal of Heat and Mass Transfer, 50(23–24), 4698–4712, 2007.

- Y. Zhang, A. Mawardi, and R. Pitchumani, “Numerical Studies on an Air-breathing Proton Exchange Membrane (PEM) Fuel Cell Stack,” Journal of Power Sources, 173, 264–276, 2007.

- A. Mawardi, Y. Xiao and R. Pitchumani, “Theoretical Analysis of Capillary-driven Nanoparticulate Slurry Flow During a Micromold Filling Process,” International Journal of Multiphase Flow, 34(3), 227–240, 2008.

- A. Mawardi and R. Pitchumani, “Numerical Simulations of an Optical Fiber Drawing Process Under Uncertainty,” IEEE Journal of Lightwave Technology, 26(5), 580–587, 2008.

- R.J. Johnson and R. Pitchumani, “Active Control of Reactive Resin Flow in a VARTM Process,” Journal of Composite Materials, 42(12), 1205–1229, 2008.

- A. Mawardi and R. Pitchumani, “Simulation of Sintering of Nanoparticulate Micropreforms in a Microfabrication Process,” Acta Materialia, 57(6), 1975–1987, 2009.

- A. Mawardi and R. Pitchumani, “Modeling of an Optical Fiber Drawing Process using an Analytical Necking Profile,” IEEE Photonics Journal, 2(4), 620–629, 2010.

- R.J. Johnson and R. Pitchumani, “Cure Kinetics and Chemorheology of Carbon Nanotube Filled Epoxy Resin Systems,” Frontiers in Heat and Mass Transfer, 1(1), 013007, 2010.

- R.J. Johnson, J. Tang, and R. Pitchumani, “Characterization of Damping in Carbon Nanotube Filled Fiberglass Reinforced Thermosetting-matrix Composites,” Journal of Materials Science, 46(13), 4545–4554, 2011.

- R. Pitchumani, “Book Review: A. Faghri, Y. Zhang, and J. Howell, Advanced Heat and Mass Transfer, Global Digital Press, 2010, 956 pp., 978-0-9842760-0-4, Hardcover, List Price: $89.95,” International Journal of Heat and Mass Transfer, 54(9–10), 2241–2242, 2011.

- S. Deb and R. Pitchumani, “Analysis of Nonisothermal Sintering of Nanocrystalline and Microscaled Ceramic Materials,” Advances in Applied Ceramics: Structural, Functional and Bioceramics, 110(5), 301–310, 2011.

- K. Nithyanandam and R. Pitchumani, “Analysis and Optimization of a Latent Thermal Energy Storage System with Embedded Heat Pipes,” International Journal of Heat and Mass Transfer, 54(21–22), 4596–4610 2011.

- A. Haghdoost and R. Pitchumani, “Numerical Analysis of Electrodeposition in Microcavities,” Electrochimica Acta, 56(24), 8260–8271, 2011.

- K. Nithyanandam and R. Pitchumani, “Analysis and Design of a Dye-Sensitized Solar Cell,” Solar Energy, 86(1), 351–368, 2012.

- C. DeValve and R. Pitchumani, “An Analytical Model for the Longitudinal Permeability of Aligned Fibrous Media,” Composites Science and Technology, 72(13), 1500—1507, 2012.

- K. Nithyanandam and R. Pitchumani, “Computational Studies on a Latent Thermal Energy Storage System with Integral Heat Pipes for Concentrating Solar Power,” Applied Energy, 103, 400—415, 2013.

- J. Stekli, L. Irwin and R. Pitchumani, “Technical Challenges and Opportunities for Concentrating Solar Power with Energy Storage,” ASME Journal of Thermal Science Engineering and Applications, 5(2), 021011, 12 pp., 2013.

- C. DeValve and R. Pitchumani, “Simulation of Void Formation in Liquid Composite Molding Processes,” Composites A: Applied Science and Manufacturing, 51, 22–32, 2013.

- C. DeValve and R. Pitchumani, “A Numerical Analysis of Carbon Nanotube based Damping in Rotating Composite Structures,” Composite Structures, 103, 18–26, 2013.

- C. DeValve and R. Pitchumani, “Experimental Investigation of the Damping Enhancement in Fiber-reinforced Composites with Carbon Nanotubes,” Carbon, 63, 71–83, 2013.

- K. Nithyanandam and R. Pitchumani, “Thermal Energy Storage with Heat Transfer Augmentation using Thermosyphons,” International Journal of Heat and Mass Transfer, 67, 281–294, 2013.

- A. Haghdoost and R. Pitchumani, “Electrodeposition in Micromolds with a Microscreen Base,” Acta Materialia, 61(20), 7568–7581, 2013.

- K. Nithyanandam, R. Pitchumani and A. Mathur, “Analysis of a Latent Thermocline Storage System with Encapsulated Phase Change Materials for Concentrating Solar Power,” Applied Energy, 113, 1446–1460, 2014.

- K. Nithyanandam and R. Pitchumani, “Computational Modeling of Dynamic Response of a Latent Thermal Energy Storage System with Embedded Heat Pipes,” ASME Journal of Solar Energy Engineering, 136(1), 011010, 9 pp., 2014.

- K. Nithyanandam and R. Pitchumani, “Cost and Performance Analysis of Concentrating Solar Power Plants with Integrated Thermal Energy Storage,” Energy, 64(1), 793–810, 2014.

- C. DeValve and R. Pitchumani, “Analysis of Vibration Damping in a Rotating Composite Beam with Embedded Carbon Nanotubes,” Composite Structures, 110, 289–296, 2014.

- K. Nithyanandam and R. Pitchumani, “Computational Studies on Metal Foam and Heat Pipe Enhanced Latent Thermal Energy Storage,” ASME Journal of Heat Transfer, 136(5), 051503, 10 pp., 2014.

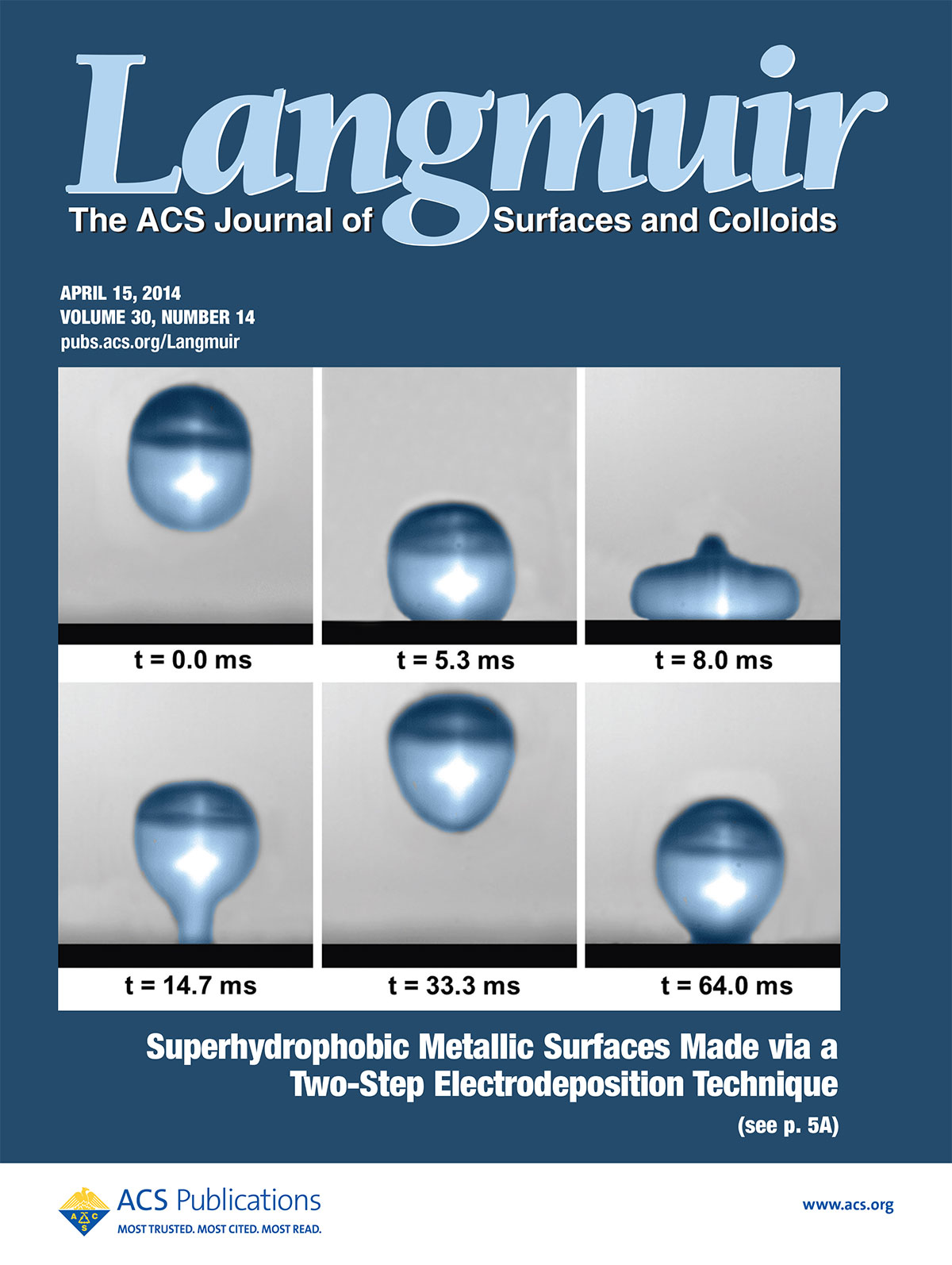

A. Haghdoost and R. Pitchumani, "Fabrication of Superhydrophobic Surfaces via a Two-Step Electrodeposition Technique", Langmuir, 30(14), 4183–4191, 2014. Cover Feature Article.

- A. Verma and R. Pitchumani, “Investigation of Mechanical Behavior of Membrane in Polymer Electrolyte Fuel Cells Subject to Dynamic Load Changes,” ASME Journal of Fuel Cell Science and Technology, 11(3), 031009, 9pp., 2014.

- K. Nithyanandam and R. Pitchumani, “Design of a Latent Thermal Energy Storage System with Embedded Heat Pipes,” Applied Energy, 126, 266–280, 2014.

- A. Donato and R. Pitchumani, “QUICKER: Quantifying Uncertainty in Computational Knowledge Engineering Rapidly—A Rapid Methodology for Uncertainty Quantification,” Powder Technology, 265, 54–65, 2014.

- R. Pitchumani, “Proceedings of the SolarPACES 2013 International Conference,” Energy Procedia, 49, 1–2, 2014.

- A. Verma and R. Pitchumani, “Influence of Membrane Properties on the Transient Behavior of Polymer Electrolyte Fuel Cells,” Journal of Power Sources, 268, 733–743, 2014.

- K. Nithyanandam and R. Pitchumani, “Optimization of a Thermocline Energy Storage System with Encapsulated Phase Change Materials,” Solar Energy, 107, 770–788, 2014.

- A. Verma and R. Pitchumani, “Effects of Operating Parameters on the Transient Response of Proton Exchange Membrane Fuel Cells Subject to Load Changes,” International Journal of Hydrogen Energy, 39(33), 19024–19038, 2014.

- A. Verma and R. Pitchumani, “Analysis and Optimization of Transient Response of Polymer Electrolyte Fuel Cells,” ASME Journal of Fuel Cell Science and Technology, 12(1), 011005, 10pp., 2015.

- A. Verma and R. Pitchumani, “Influence of Transient Operating Parameters on the Mechanical Behavior of Fuel Cells,” International Journal of Hydrogen Energy, 40(26), 8442–8453, 2015.

- Y. Zhang, A. Smirnova, A. Verma and R. Pitchumani, “Design of a Proton Exchange Membrane (PEM) Fuel Cell with Variable Catalyst Loading,” Journal of Power Sources, 291, 46–57, 2015.

- Y. Zhang, A. Verma and R. Pitchumani, “Studies on Graded Porosity Distributions of Gas Diffusion Layer in Proton Exchange Membrane (PEM) Fuel Cells,” International Journal of Hydrogen Energy, 41, 8412–8426, 2016.

- K. Nithyanandam and R. Pitchumani, “Thermal and Structural Investigation of Tubular Supercritical Carbon Dioxide Power Tower Receivers,” Solar Energy, 135, 374–385, 2016.

- J. Deshpande, K. Nithyanandam and R. Pitchumani, “Analysis of a Direct Contact Membrane Distillation System for Desalination,” Journal of Membrane Science, 523C, 301–316, 2017.

- A. Verma and R. Pitchumani, “Fractal Description of Microstructures and Properties of Dynamically Evolving Porous Media,” International Communications in Heat and Mass Transfer, 81, 51–55, 2017.

- R. Pitchumani, “Progress in Solar Energy Special Issue: Advances in Concentrating Solar Power,” Solar Energy, 152, 1–2, 2017.

- R. Jain and R. Pitchumani, “Fractal Model for Wettability of Rough Surfaces,” Langmuir, 33(28), 7181–7190, 2017.

- R. Jain and R. Pitchumani, “Fabrication and Characterization of Multiscale, Fractal Textured Solar Selective Coatings,” Solar Energy Materials and Solar Cells, 172C, 213–219, 2017.

- K. Nithyanandam, J. Deshpande and R. Pitchumani, “Coupled Thermal and Optical Analysis a Planar Waveguide Concentrator-Receiver,” Applied Energy, 208, 1576–1589, 2017.

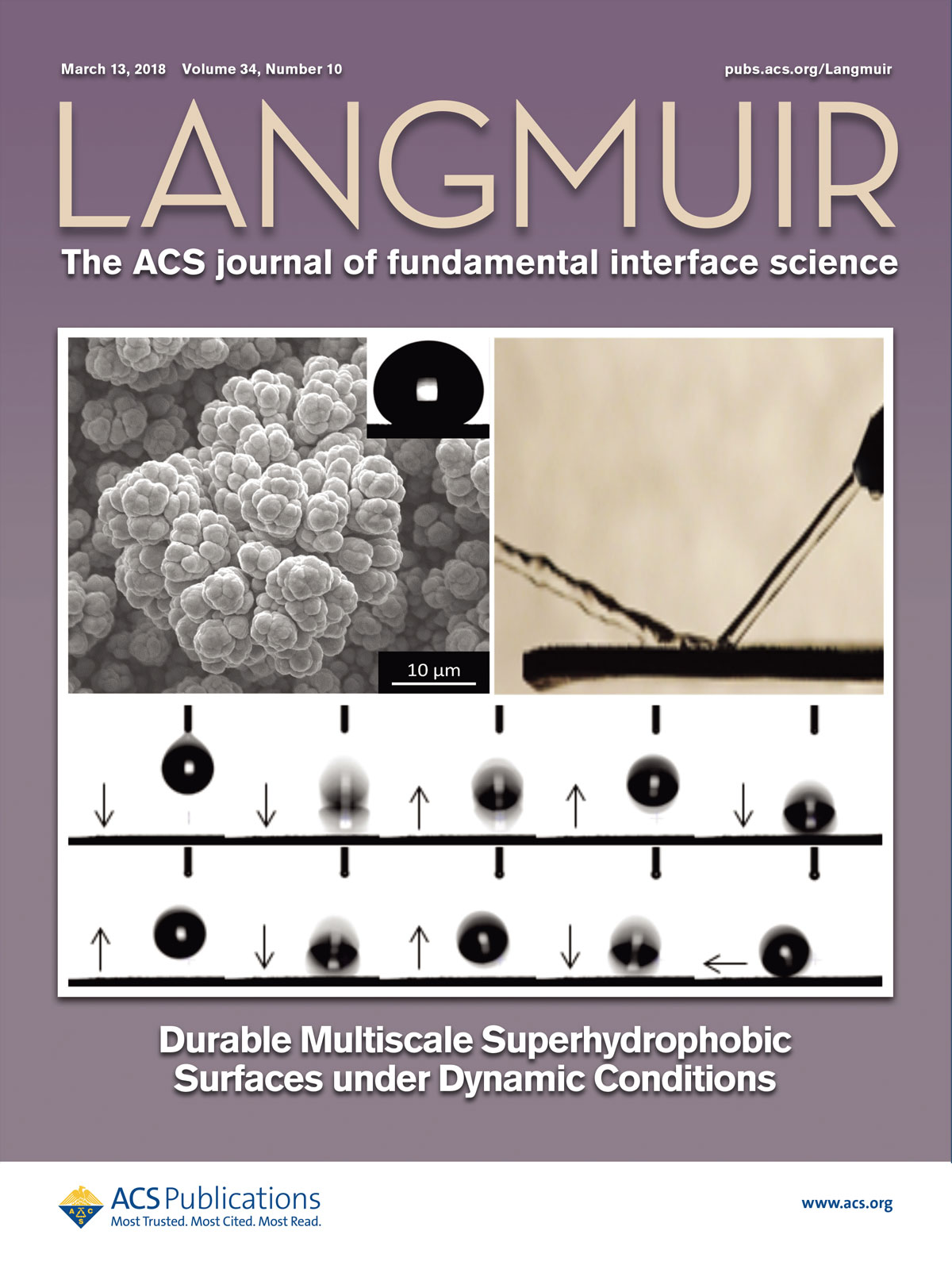

R. Jain and R. Pitchumani, “Facile Fabrication of a Robust Copper-based Superhydrophobic Surface via Electrodeposition,” Langmuir, 34(10), 3159–3169, 2018. Cover Feature Article.

- R. Jain and R. Pitchumani, “Fabrication and Characterization of Durable Zinc Based Superhydrophobic Coatings,” Surface and Coatings Technology, 337, 223–231, 2018.

- K. Nithyanandam, A. Narayan and R. Pitchumani, “Analysis and Design of a Radial Waveguide Concentrator for Concentrated Solar Thermal Applications,” Energy, 151, 940–953, 2018.

- K. Kant, R. Pitchumani, A. Shukla, and A. Sharma, “Analysis and Design of Air Ventilated Building Integrated Photovoltaic (BIPV) System Incorporating Phase Change Materials,” Energy Conversion and Management, 196, 149–164, 2019.

- A. Narayan and R. Pitchumani, “Analysis of an Air-Cooled Air Gap Membrane Distillation Module,” Desalination, 475C, 114179, 2020.

- S. Hatte and R. Pitchumani, “Fractal Model for Laminar Drag Reduction on Multiscale Liquid Infused Rough Surfaces,” Langmuir, 36(47), 14386–14402, 2020.

- K. Kant and R. Pitchumani, “Laminar Drag Reduction in Microchannels with Liquid Infused Textured Surfaces,” Chemical Engineering Science, 230, 116196, 2021.

- S. Hatte and R. Pitchumani, “Analytical Model for Drag Reduction on Liquid-Infused Structured Non-Wetting Surfaces,” Soft Matter, 17, 1388–1403, 2021.

- S. Hatte and R. Pitchumani, “Analysis of Laminar Convective Heat Transfer Over Structured Non-Wetting Surfaces,” International Journal of Heat and Mass Transfer, 167, 120810, 2021.

- S. Bhavsar and R. Pitchumani, “A Novel Machine Learning Based Identification of Potential Adopter of Rooftop Solar Photovoltaics,” Applied Energy, 286, 116503, 2021.

- R. Stoddard, K. Nithyanandam and R. Pitchumani, “Steam Condensation Heat Transfer on Lubricant Infused Surfaces,” Invited Article, iScience, 24(4), 102336, 2021.

- K. Kant, K. Nithyanandam, and R. Pitchumani, “Analysis and Optimization of a Novel Hexagonal Waveguide Concentrator for Solar Thermal Applications,” Energies, 14, 2146, 2021.

- K. Nithyanandam, P. Shoaei and R. Pitchumani, “Technoeconomic Analysis of Thermoelectric Power Plant Condensers with Nonwetting Surfaces,” Invited Article, Energy, 227, 120540, 2021.

- S.M.A. Mousavi and R. Pitchumani, “A Study of Corrosion on Electrodeposited Superhydrophobic Copper Surfaces,” Corrosion Science, 186, 109420, 2021.

- S. Bhavsar, R. Pitchumani and M.A. Ortega-Vazquez, “Machine Learning Enabled Reduced-order Scenario Generation for Stochastic Analysis of Solar Power Forecasts,” Applied Energy, 293, 116964, 2021.

- S. Hatte and R. Pitchumani, “Analysis of Convection Heat Transfer on Multiscale Rough Superhydrophobic and Liquid Infused Surfaces," Chemical Engineering Journal, 424, 130256, 2021.

- P. Kondaiah and R. Pitchumani, “Fractal Textured Surfaces for High Temperature Corrosion Mitigation in Molten Salts,” Solar Energy Materials and Solar Cells, 230, 111281, 2021.

- S.M.A. Mousavi and R. Pitchumani, “Bioinspired Nonwetting Surfaces for Corrosion Inhibition over a Range of Temperature and Corrosivity,” Journal of Colloid and Interface Science, 607, 323-333, 2022.

- R. Stoddard, K. Nithyanandam and R. Pitchumani, “Fabrication and Durability Characterization of Superhydrophobic and Lubricant-Infused Surfaces,” Journal of Colloid and Interface Science, 608, 662–672, 2022.

- S.M.A. Mousavi and R. Pitchumani, “Temperature-dependent Dynamic Fouling on Superhydrophobic and Slippery Nonwetting Copper Surfaces,” Chemical Engineering Journal, 431, 133960, 2022.

- A. Sharma, R. Pitchumani, R. Chauhan, “Solar Air Heating Systems with Latent Heat Storage – A Review of State-of-the-art,” Journal of Energy Storage, 48, 104013, 2022.

- S. Hatte, R. Stoddard and R. Pitchumani, “Generalized Analysis of Dynamic Flow Fouling on Heat Transfer Surfaces,” International Journal of Heat and Mass Transfer, 188, 122573, 2022.

- S.M.A. Mousavi and R. Pitchumani, “A Comparative Study of Mechanical and Chemical Durability of Non-wetting Superhydrophobic and Lubricant-Infused Surfaces,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, 643, 128711, 2022.

- K. Kant and R. Pitchumani, “Analysis of a Novel Constructal Fin Tree Embedded Thermochemical Energy Storage for Buildings Applications,” Energy Conversion and Management, 258, 115542, 2022.

- S. Hatte and R. Pitchumani, “Analysis of Silica Fouling on Nonwetting Surfaces,” Soft Matter, 18, 3403-3411, 2022.

- P. Kondaiah and R. Pitchumani, “Fractal Coatings of Ni and NiYSZ for High-Temperature Corrosion Mitigation in Solar Salt,” Corrosion Science, 201, 110283, 2022.

- S.M.A. Mousavi and R. Pitchumani, “Long-term Static and Dynamic Corrosion Stability of Nonwetting Surfaces,” Langmuir, 38(22), 6911–6922, 2022.

- K. Kant and R. Pitchumani, “Advances and Opportunities in Thermochemical Heat Storage Systems for Buildings Applications,” Applied Energy, 321, 119299, 2022.

- S. Bhavsar, R. Pitchumani and M. A. Ortega-Vazquez, “A Reforecasting-Based Dynamic Reserve Estimation for Variable Renewable Generation and Demand Uncertainty,” Electric Power Systems Research, 211, 108157, 2022.

- A. Shukla, K. Kant, P.H. Biwole, R. Pitchumani, A. Sharma, “Melting and Solidification of a Phase Change Material with Constructal Tree-Shaped Fins for Thermal Energy Storage,” Journal of Energy Storage, 53, 105158, 2022.

- S. Hatte and R. Pitchumani, “Novel Nonwetting Solid-Infused Surfaces for Superior Fouling Mitigation,” Journal of Colloid and Interface Science, 627, 308–319, 2022.

- S. Hatte and R. Pitchumani, “Effects of Temperature on Flow Fouling of Smooth and Nonwetting Surfaces,” Industrial & Engineering Chemistry Research, 61(38), 14355–14363, 2022.

- K. Kant and R. Pitchumani, “Fractal Textured Glass Surface for Enhanced Performance and Self-Cleaning Characteristics of Photovoltaic Panels,” Energy Conversion and Management, 270, 116240, 2022.

- K. Kant, K.P. Sibin and R. Pitchumani, “Novel Fractal-textured Solar Absorber Surfaces for Concentrated Solar Power,” Solar Energy Materials and Solar Cells, 248, 112010, 2022.

- S.M.A. Mousavi and R. Pitchumani, “Mineral Scaling on Brass and Aluminum Surfaces with a Range of Wettability,” Surfaces and Interfaces, 34, 102379, 2022.

- P. Kondaiah and R. Pitchumani, “Novel Textured Surfaces for Superior Corrosion Mitigation in Molten Carbonate Salts for Concentrating Solar Power,” Renewable and Sustainable Energy Reviews, 170, 112961, 2022.

- S. Hatte, R. Stoddard and R. Pitchumani, “Novel Solid-Infused Durable Nonwetting Surfaces for Sustained Condensation Heat Transfer Enhancement,” Applied Thermal Engineering, 219, 119458, 2023.

- S. Bhavsar, K. Kant and R. Pitchumani, “Robust Model-Predictive Thermal Control of Lithium-Ion Batteries under Drive Cycle Uncertainty,” Journal of Power Sources, 557, 232496, 2023.

- K. Kant and R. Pitchumani, “Analysis and Design of Battery Thermal Management Under Extreme Fast Charging and Discharging,” Journal of Energy Storage, 60, 106501, 2023.

- P. Kondaiah and R. Pitchumani, “Progress and Opportunities in Corrosion Mitigation in Heat Transfer Fluids for Next-generation Concentrating Solar Power,” Renewable Energy, 205, 956–991, 2023.

- A. Sharma, R. Pitchumani, and R. Chauhan, “Melting and Solidification Performance Investigation of Latent Heat Storage Unit Designs for Low-temperature Solar Thermal Applications,” Journal of Energy Storage, 60, 107323 , 2023.

- S. Bhavsar, R. Pitchumani, M.A. Ortega-Vazquez, and N. Costilla-Enriquez, “A Hybrid Data-driven and Model-based Approach for Computationally Efficient Stochastic Unit Commitment and Economic Dispatch Under Wind and Solar Uncertainty,” International Journal of Electrical Power & Energy Systems, 151, 109144, 2023.

- A.M. Fuller and R. Pitchumani, “Long Term Durability of a Lubricant-Infused Surface for Dew Harvesting,” Langmuir, 39(28), 9885–9892, 2023.

- S. Hatte, K. Kant, and R. Pitchumani, “Freezing Characteristics of a Water Droplet on a Multiscale Superhydrophobic Surface,” Langmuir, 39(33), 11898–11909, 2023.

- S. Bhavsar, R. Pitchumani, M. Reynolds, N. Merket, and J. Reyna, “Machine Learning Surrogate of Physics-Based Building-Stock Simulator for End-Use Load Forecasting,” Energy and Buildings, 296, 113395, 2023.

- K.P. Sibin, K. Kant, and R. Pitchumani, “High-Temperature Air Stability of Electrodeposited Copper Cobalt Oxide and Copper Manganese Oxide Absorber Coatings for Concentrating Solar Power,” ACS Applied Energy Materials, 6(17), 8759–8774, 2023.

- P. Kondaiah and R. Pitchumani, “Electrodeposited Nickel Coatings for Exceptional Corrosion Mitigation in Industrial Grade Molten Chloride Salts for Concentrating Solar Power,” Renewable and Sustainable Energy Reviews, 189, Part B, 113848, 2024.

- A. Fuller, K. Kant, and R. Pitchumani, “Analysis of Freezing of a Sessile Water Droplet on Surfaces over a Range of Wettability,” Journal of Colloid and Interface Science, 653, Part A, 960–970, 2024.

- K. Kant and R. Pitchumani, “Erosion Wear Analysis of Heat Exchange Surfaces in a Falling Particle-Based Concentrating Solar Power System,” Solar Energy Materials and Solar Cells, 264, 112629, 2024.

- S. Bhavsar, R. Pitchumani, J. Maack, I. Satkauskas, M. Reynolds, W. Jones, “Stochastic Economic Dispatch of Wind Power under Uncertainty using Clustering-based Extreme Scenarios,” Electric Power Systems Research, 229, 110158, 2024.

- P. Kondaiah and R. Pitchumani, “Influence of Corrosion-Resistant Coatings on the Post-Corrosion Thermal Stability and Fouling of Molten Salts for High Temperature Thermal Energy Storage,” Journal of Energy Storage, 92, 111961, 2024.

- S. Hatte, R. Stoddard, and R. Pitchumani, “Novel Nonwetting Surfaces for Enhanced Condenser Performance in Thermal Power Plants,” Thermopedia, Begell House, Inc., 2024.

- A. Sharma, M. Khatamifar, W. Lin, and R. Pitchumani, “A State-of-the-art Review on Numerical Investigations of Liquid-Cooled Battery Thermal Management Systems for Lithium-Ion Batteries of Electric Vehicles,” Journal of Energy Storage, 101, Part B, 113844, 2024.

- S. Hatte and R. Pitchumani, “Limits of Dropwise Condensation Heat Transfer on Dry Nonwetting Surfaces,” iScience, 27(11), 111059, 2024.

- K. Kant and R. Pitchumani, “Analysis of Abrasion Wear in Particle Storage and Valve Subsystem for Falling Particle Concentrating Solar Power,” Tribology International, 201, 110259, 2025.

- K.P. Sibin and R. Pitchumani, “Multiscale Textured Solar Absorber Coatings for Next-Generation Concentrating Solar Power,” Renewable and Sustainable Energy Reviews, 207, 114959, 2025.

- K. Kant, P. Kondaiah, and R. Pitchumani, “Analysis of Erosion of Surfaces in Falling Particle Concentrating Solar Power,” ASME Journal of Solar Energy Engineering, 147(2), 021010, 11 pp., 2025.

- K. Kant and R. Pitchumani, “Analysis and Mitigation of Erosion Wear of Transfer Ducts in a Falling Particle CSP System,” Wear, 562-563, 205619, 2025.

- K.P. Sibin and R. Pitchumani, “Bimetallic Cobalt-Nickel Oxide Textured Coatings for High-Temperature Concentrated Solar Power,” Journal of Alloys and Compounds, 1010, 178220, 2025.

- K. Nithyanandam, K. Kant, P. Kondaiah, and R. Pitchumani, “Technoeconomics of a molten salt/supercritical carbon dioxide heat exchanger with fractal-textured corrosion resistant coatings for concentrating solar thermal systems,” Energy Conversion and Management, 341, 120028, 2025.

- P. Kondaiah, K. Kant, and R. Pitchumani, “Effects of Thermally Grown Oxides on Erosion Wear of Surfaces at High Temperature for Falling Particle Concentrating Solar Power,” Solar Energy Materials and Solar Cells, 292, 113800, 2025.

- K. Kant and R. Pitchumani, “Analysis and design of a particle heat exchanger for falling particle concentrating solar power,” Chemical Engineering Journal, 525, 170028, 2025.

- K.P. Sibin and R. Pitchumani, “High-performance Multilayer Cobalt-Nickel Oxide Solar Absorber Coatings for Next Generation Concentrated Solar Thermal Systems,” Energy Conversion and Management, 347, 120622, 2026.

D. Conference Publications

- R. Pitchumani and S.C. Yao, “Fractal-based Correlation for the Evaluation of Thermal Conductivities of Fibrous Composites,” Transport Phenomena in Materials Processing, ASME–HTD–146, 55–60, 1990.

- R. Pitchumani and S.C. Yao, “Analysis of Continuous Formation of Sheet-laminated Composites,” in First International Conference on Transport Phenomena in Processing, S.I. Güçeri ed., 1330–41, 1992.

- R. Pitchumani, S.C. Yao, P. K. Liaw, R. E. Shannon and D. K. Hsu, “A Simplified Model for Estimating the Anisotropic Conductivities of Al/SiCp Composites for Process Monitoring” Transport Phenomena in Materials Processing and Manufacturing, ASME–HTD–196, 201–207, 1992.

- R. Pitchumani, P.K. Liaw, et al., “Modeling Anisotropic Conductivity Behavior of SiCp/Al Metal-Matrix Composite Extrusions,” in Review of Progress in Quantitative Nondestructive Evaluation. Plenum Press 12B, pp. 1329-1336, 1992.

- R. Pitchumani, P.K. Liaw and S.C. Yao, “Nondestructive Conductivity Measurements on Metal–matrix Composites,” TMS Annual Meeting, 1992.

- R. Pitchumani, P. K. Liaw, D. K. Hsu, H. Jeong and S. C. Yao, “Determination of Reinforcement and Intermetallics Concentrations in SiCp/Al Metal Matrix Composites Using Eddy Current Techniques,” Second Annual ASNT Research Symposium, 1993.

- R. Pitchumani and U.M. Diwekar, “Optimal Cure Cycles for Thermoset Composites Manufacture,” in Adv. Computations in Materials Processing, V. Prasad, R. V. Arimilli eds., ASME–HTD–241, 23–31, 1993.

- R. Pitchumani, P.K. Liaw, D.K. Hsu, H. Jeong and S.C. Yao, “Nondestructive Evaluation of Anisotropic Conductivities of SiCp/Al Composite Extrusions,” ASME Paper 93–GT–15, 1993.

- R. Pitchumani, V.M. Karbhari, J.F. Ramsay and T.D. Claar, “A Knowledge–based Decision Support System for the Manufacture of Composite Preforms,” in Advanced Materials: Expanding the Horizons, R. Trabacco and T. Lynch eds., Intl. SAMPE Technical Series, 25, 1069–81, 1993.

- R. Pitchumani, R. C. Don and J. W. Gillespie, Jr., “Simulation of the Transients in Thermoplastic Fiber Placement,” in Moving Forward with 50 Years of Leadership in Advanced Materials, K. Drake et al. eds., International SAMPE Series, 39(1), 1521–1535, 1994.

- R. Pitchumani and U. M. Diwekar, “Process Optimization for the Fabrication of Partially-cured Composites,” in Transport Phenomena in Manuf. & Materials Proc., ASME–HTD–280, 1–11, 1994.

- R. Pitchumani, “A Fractal Geometry Approach to Modeling Disordered Composite Microstructures and their Properties,” in Proceedings, 9th Technical Conference of the American Society for Composites, T. W. Chou and J. Vinson, eds., pp. 807–817, 1994.

- R. Pitchumani, R. C. Don, S. Ranganathan and J. W. Gillespie, Jr., “Analysis of On–line Consolidation During the Thermoplastic Fiber Placement Process,” in Thermal Processing of Materials: Thermomechanics, Controls, and Composites, ASME–HTD–289, 223–234, 1994.

- R. Pitchumani, R. C. Don, S. Ranganathan and J. W. Gillespie, Jr., “Effects of Processing Conditions on Void Growth During Thermoplastic Fiber Placement,” in Mechanics in Materials Processing & Manufacturing, ASME–AMD–194, 71–87, 1994.

- R. Pitchumani and V.M. Karbhari, “Knowledge-based Decision Support Systems for Rapid and Efficient Production Planning in CMC Fabrication,” Ceramic Engineering & Science Proceedings, 15, 932–939, 1994.

- C.A. Butler, R. Pitchumani, A. G. Wedgewood and J. W. Gillespie, Jr., “Coupled Effects of Healing and Intimate Contact on the Strength of Fusion-bonded Thermoplastics,” in Proceedings of the Tenth Annual ASM/ESD Advanced Composites Conference, 595–604, 1994.

- C.A. Butler, R. Pitchumani, A.G. Wedgewood and R.L. McCullough “An Improved Model for the Bond Strength of Fusion-bonded Thermoplastics,” Presented at the AIChE Annual Meeting, 1994.

- R. Pitchumani, K.V. Steiner and B.M. Bauer “Experimental Verification of Modeling and Control for Thermoplastic Tow Placement,” in Proc. 40th Int. SAMPE Symp. & Exhibition, 1550–59, 1995.

- D. L. Fecko, R. C. Don, R. Pitchumani, and J. W. Gillespie, Jr., “Porosity Modeling for Thermoplastic Pultrusion,” in Proceedings of the 11th Annual ASM/ESD Advanced Composites Conference, pp. 189–201, 1995.

- P.C. Chaudhury, U.M. Diwekar, and R. Pitchumani, “Characterization of Accuracy of Sampling Techniques for Chemical Process Synthesis under Uncertainties,” AIChE National Meeting, Nov. 1995.

- D. Sadagopan and R. Pitchumani, “Property-based Optimal Tailoring of Composite Materials,” in Physical Properties of Composites, P. K. Liaw and R. Pitchumani, eds., pp. 1–10, 1996.

- R. Pitchumani and P.K. Liaw, “Investigations on Eddy Current Evaluation of Metal-Matrix Composites,” in Physical Properties of Composites, P. K. Liaw and R. Pitchumani, eds., pp. 19–30, 1996.

- N. Rai and R. Pitchumani, “Application of Neural Networks to Optimization of Cure Cycles for the Manufacture of Composites,” ASME Paper 96-WA/AMD-9, 1996.

- B. Ramakrishnan and R. Pitchumani, “Fractal Permeation Characteristics of Preforms Used in Liquid Composite Molding,” Proceedings of the NSF Grantees Conference, pp. 341–342, 1997.

- S.K. Padmanabhan and R. Pitchumani, “Stochastic Analysis of the Resin Transfer Molding Process,” In: Proceedings, 12th Tech. Conf. American Society for Composites, R. Gibson and G. Newaz, eds., pp. 797–806, 1997.

- B. Ramakrishnan and R. Pitchumani, “A Fractal Geometry Approach to Evaluating the Permeabilities of Preforms Used in Liquid Composite Molding,” In: Proceedings, 12th Tech. Conf. of the Amer. Soc. for Composites, R. Gibson and G. Newaz, eds., pp. 846–855, 1997.

- L. VanDerSchuur and R. Pitchumani, “A LabVIEW-based Cure Temperature Control System for Composites Processing,” LabVIEW Virtual Instrumentation Education Conference, 1997.

- B. Ramakrishnan and R. Pitchumani, “Fractal Permeation Model for Preform Infiltration During Liquid Composite Molding,” MRS Annual Meeting, 1997.

- S. K. Padmanabhan and R. Pitchumani, “Effects of Process Parameter Uncertainties on Nonisothermal Mold Filling During RTM,” Proceedings of the International SAMPE Symposium and Exhibition, 43(2), pp. 1275–1288, 1998.

- B. Ramakrishnan, L. Zhu and R. Pitchumani, “Accelerated Curing of Composites Using Supplemental Internal Resistive Heating,” Proceedings, Int. SAMPE Symposium & Exhibition, 43(1), pp. 243–253, 1998.

- P.D. Lafferty and R. Pitchumani, “An Intelligent Model-Predictive Process Control Framework for RTM,” in: Proceedings of the Conference of the American Society for Composites, pp. 213–225, 1998.

- F. Yang and R. Pitchumani, “A Fractal Model for Intimate Contact Development During Thermoplastic Fusion Bonding,” in: Proceedings, 13th Technical Conference of the American Society for Composites, A. J. Vizzini, ed., pp. 1134–1146, 1998.

- L. Zhu and R. Pitchumani, “Processing Envelopes for Supplemental Internal Resistive Heating during Thermosetting Composites Cure,” Proceedings of the Eighth Japan-US Conference on Composites, G. Newaz and R. Gibson, eds., pp. 122–132, 1998.

- F. Yang and R. Pitchumani, “Fractal Description of Interlaminar Contact Development During Thermoplastic Composites Processing,” Proceedings ANTEC 99 Conference, Society of Plastics Engineers, pp. 1316–1320, 1999.

- D. Nielsen and R. Pitchumani, “Intelligent Simulation-based Optimal Control of Liquid Composite Molding Processes,” Invited Presentation, On-line Sensing and Control for Resin Transfer Molding of Composites, Annapolis, MD, April 14–15, 1999.

- R. Pitchumani, “Innovative Strategies for Modeling and Processing of Composite Materials,” Invited Presentation, Gordon Research Conference on Composites, Ventura, CA, January 12, 2000.

- X. Guan and R. Pitchumani, “Novel Synthesis of Hierarchical, Multiscale Fibrous Composites," in Proceedings of the 2000 NSF Design & Manufacturing Research Conf., Jan 3-6, 2000, Vancouver, BC, 4pp.

- B. Ramakrishnan, L. Zhu and R. Pitchumani, “Resistive Curing of Composite Materials,” in Proceedings of the 2000 NSF Design & Manufacturing Research Conference, January 3-6, 2000, Vancouver, BC, 10pp.

- D. Nielsen and R. Pitchumani, “Real-Time Model-Predictive Control of Preform Permeation in Liquid Composite Molding Processes,” in Advances for Sensing and Control of Thermal Processing in Manufacturing, ASME Edited CD Volume, 0-7918-1997-3, 1463CD, National Heat Transfer Conference, Topic Area: T9-35, Paper No. NHTC2000-12158, 10 pp.

- S. Streeseman and R. Pitchumani, “Stochastic Analysis of a Composite Manufacturing Process,” SIAM Conference on Computational Science and Engineering: Symposium on Optimization Under Uncertainty, September 21–24, 2000, Washington D.C.

- F. Yang and R. Pitchumani, “Modeling Interphase Development in Thermosetting Matrix Composites,” in Proceedings of the Heat Transfer Division—2000, ASME HTD-Vol. 366-3, pp. 329–338, 2000.

- D. Nielsen and R. Pitchumani, “Control of Flow in Resin Transfer Molding with Real-time Permeability Estimation,” in Proceedings of the Heat Transfer Division—2000, ASME HTD-Vol. 366-3, pp. 159–170, 2000.

- F. Yang and R. Pitchumani, “Kinetics of Interphase Formation in Thermosetting Composites,” 16th Technical Conference of the American Society for Composites, Blacksburg, VA, September, 2001.

- F. Yang and R. Pitchumani, “A Nonisothermal Healing Model for in-situ Processing of Thermoplastic Matrix Composites,” Symposium on Polymer and Composite Materials Processing, Paper No. IMECE2001/HTD-24363, CD ROM Proceedings, ASME IMECE, 2001, NY.

- A. Mawardi and R. Pitchumani, “Optimization of Cure Cycles for Thermosetting Composites Fabrication under Uncertainty,” INFORMS (Institute for Operations Research and the Management Sciences) International Conference, June, 2001, Maui, Hawaii.

- F. Yang and R. Pitchumani, “Studies on Fiber/Matrix Interphase Development in Thermosetting-Matrix Composites,” Heat Transfer 2002: Proceedings of the 12th International Heat Transfer Conference, Vol. 3, pp. 153–158, Elsevier, 2002.

- R.J. Johnson and R. Pitchumani, “Induction Heating Assisted Permeation Enhancement for the VARTM Process,” International SAMPE Technical Conference, Vol. 34, pp. 250–261, 2002.

- A.M. Morales, R. Pitchumani and A.K. Gutmann, “Micromolding of Nanoparticle Preforms for the Fabrication of High Aspect Ratio Microdevices,” To be presented at the HARMST (High Aspect Ratio Microsystems Technology) 2003 Conference, Monterrey, CA, June 2003.

- R.J. Johnson and R. Pitchumani, “Simulation of Active Control of VARTM Using Induction Heating,” International Conference on Composite Materials (ICCM), 2003.

- F. Yang and R. Pitchumani, “Effects of Process and Material Parameters on the Interphase, and the Relationship to Mechanical Properties of Thermosetting Matrix Composites,” International Conference on Composite Materials (ICCM), 2003.

- F. Yang and R. Pitchumani, “Processing-Interphase Relationships for the Curing of Thermosetting-matrix Composites,” SAMPE Technical Conference, Dayton OH, October 2003.

- Q. Jiang, R. Pitchumani, A.M. Morales and L.A. Domeier, “Analysis of a Process for Replication of Electroforming Molds with Integral Microscreens,” Proceedings of the SPIE International Society for Optical Engineering 5342, 156, 2004.

- F. Yang and R. Pitchumani, “Characterization of the Interphase Formation Kinetics in Thermosetting-Matrix Composites,” SAMPE 2004, Long Beach, CA, May 16–20, 2004.

- V. Mishra, F. Yang and R. Pitchumani, “Electrical Contact Resistance Between Gas Diffusion Layers and Bipolar Plates in a PEM Fuel Cell,” Second International Conference on Fuel Cell Science, Engineering and Technology, Rochester, NY, Vol. FUELCELL2004-2529, pp. 613–619, 2004.

- R.J. Johnson and R. Pitchumani, “Active Flow Control in a VARTM Process Using Localized Induction Heating,” FPCM7: Seventh International Conference on Flow Processes in Composite Materials, S.G. Advani, ed., pp. 247–252, 2004.

- Y. Zhang, A. Mawardi and R. Pitchumani, “Analysis and Design of Proton Exchange Membrane Fuel Cells for Maximum Power Density and Uniform Current Density Distribution,” First European Fuel Cell Technology & Applications Conference, Dec 2005, Rome, Italy.

- R. Pitchumani, “Interphase in Thermosetting-Matrix Composites,” Invited Presentation, Panel on Multiscale Modeling for Carbon Fiber Reinforced Composites, SAMPE 2006, Long Beach, CA, 2006.

- Y. Xiao, A. Mawardi and R. Pitchumani, “Flow of Nanoparticulate Slurry During a Microcasting Process for the Fabrication of Metallic and Ceramic Microstructures,” in Proceedings of the 13th International Heat Transfer Conference, August 13–18, 2006, Sydney, Australia, Paper No. NAN-04, 12 pp. ISBN 1-56700-226-9, Begell House, Inc., Redding, CT.

- A. Mawardi, R. Pitchumani and A.M.Morales, “Multiscale Simulation of Sintering of Nanoparticulate Micropreforms in a Microfabrication Process,” Paper MNC2007-21575 ASME International Conference on Integration and Commercialization of Micro and Nanosystems, Sanya, Hainan, China, Jan 10–13, 2007, ISBN 0-7918-3794-7, ASME, NY.

- R. Pitchumani, “Novel Designs of Proton Exchange Membrane (PEM) Fuel Cells,” Keynote Presentation, Special Symposium in Honor of Professor Suhas P. Sukhatme (Indian Institute of Technology, Bombay), Hyderabad, India, Jan. 2, 2008; in A Festschrift in Honour of Professor Suhas P. Sukhatme, U.N. Gaitonde, et al., eds., pp. 23–26, Research Publishing, Singapore, 2008.

- R.J. Johnson and R. Pitchumani, “Localized Induction Heating Based Control of Reactive Resin Flow in the VARTM Process,” Invited Paper, in Proceedings of the 9th International Conf. on Flow Processes in Composite Materials (FPCM9), July 8–10, 2008, Montreal, Canada..

- R.J. Johnson and R. Pitchumani, “Chemorheology and Cure Kinetics of a Carbon Nanotube Filled Epoxy System,” ICCM-17 17th International Conference on Composite Materials, 27–31 Jul 2009, Edinburgh, UK, CD ROM Volume, 9 pp.

- C. DeValve and R. Pitchumani, “Void Formation During Preform Impregnation in Liquid Composite Molding Processes,” 10th International Conference on Flow Processes in Composite Materials, Ascona, Switzerland, July 11–15, 2010.

- J. Chen and R. Pitchumani, “Dispersion of Carbon Nanotubes in Resin Systems using Chaotic Mixing,” 10th Intl. Conf. on Flow Processes in Composite Materials, Switzerland, July, 2010.

- K. Nithyanandam and R. Pitchumani, “Analysis and Design of Dye-Sensitized Solar Cell Installation,” Paper No. IHTC14-23101, Proceedings,14th International Heat Transfer Conference, Washington D.C., 2010, ISBN 978-0-7918-3879-2.

- A. Haghdoost and R. Pitchumani, “Electrodeposition in Polymeric Micromolds for the Fabrication of Metallic Microstructures,” Paper No. IMECE2010-37751, ASME International Mechanical Engineering Congress and Exposition, Vancouver, British Columbia, Canada, November 12–18, 2010, ISBN 978-0-7913-3879-2.

- K. Nithyanandam and R. Pitchumani, “Numerical Modeling of a Latent Heat Thermal Energy Storage System with Integral Heat Pipes,” Paper No. IMECE2010-38682, ASME International Mechanical Engineering Congress & Expo, 2010.

- J. Chen and R. Pitchumani, “Computational Modeling of Polymer Flow in Microcavities through a Microscreen,” Paper No. IMECE2010-38675, ASME International Mechanical Engineering Congress and Exposition, Vancouver, British Columbia, Canada, November 12–18, 2010, CD Volume, ISBN 978-0-7913-3879-2.

- K. Nithyanandam and R. Pitchumani, “Computational Modeling of Dynamic Response of a Latent Thermal Energy Storage System With Embedded Heat Pipes,” Paper No. ESFuelCell2011-54501, 5th International Conference on Energy Sustainability, 2011.

- C. DeValve and R. Pitchumani, “A Numerical Simulation of Air Entrapment During Resin Transfer Molding,” SAMPE 2011, May 23–26, 2011, Long Beach, CA.

- A. Haghdoost and R. Pitchumani, “Modeling of Microfabrication by Electrodeposition Through a Microscreen-Based LIGA Mold,” Abstract ID: 223815, AIChE Annual Meeting, October 16-21, 2011, Minneapolis, MN.

- A. Donato, R. Pitchumani and M. Shahnam, “A Computationally Efficient Approach to Uncertainty Quantification in Multiphase Systems,” NETL 2012 Conference on Multiphase Flow Science, NRCCE, May 22-24, 2012, Morgantown, WV.

- K. Nithyanandam, R. Pitchumani and A. Mathur “Analysis of a Latent Thermocline Energy Storage System for Concentrating Solar Power Plants,” Paper No. ESFuelCell2012-91389, 6th International Conference on Energy Sustainability, 2012.

- K. Nithyanandam and R. Pitchumani, “Numerical Analysis of Latent Thermal Energy Storage System with Embedded Thermosyphons,” Paper No. ESFuelCell2012-91416, 6th International Conference on Energy Sustainability, 2012.

- A. Haghdoost and R. Pitchumani, “Formation of Three-Dimensional Nanostructures During Electrodeposition Process,” Fall Meeting of the Materials Research Society, 2012, Boston, MA.

- A. Donato and R Pitchumani, “Analysis of the Effects of Pressure Drop and Flow Distribution in Fixed Bed Reactors for Carbon Capture,” The 12th CCUS Conference Pittsburgh 2013.

- C. DeValve, P.A. Tarazaga, R. Pitchumani and N. Ameri, “Modal Analysis of Rotating Carbon Nanotube Infused Composite Beams,” Chapter 52 in R. Allemang et al. (eds.), Topics in Modal Analysis, Volume 7: Proceedings of the 31st IMAC, A Conference on Structural Dynamics, 2013, Vol. 45, The Society for Experimental Mechanics.

- A. Haghdoost and R. Pitchumani, “Super-Repellancy via Controlled Topography of Particle-Coated Surfaces,” in Proceedings of the 36th Annual Meeting of the Adhesion Society, 2013.

- A. Donato and R. Pitchumani, “Quantifying Uncertainty in Computational Knowledge Engineering Rapidly (QUICKER),” Paper No. V&V2013-2235, ASME 2013 Verification and Validation Symposium, May 22-24, 2013, Las Vegas, NV.

- K. Nithyanandam and R. Pitchumani, “Techno-Economic Analysis of Concentrating Solar Power Plants with Integrated Latent Thermal Storage Systems,” Paper No. ES-FuelCell2013-18213, 7th International Conf. Energy Sustainability, 2013.

- K. Nithyanandam and R. Pitchumani, “Design and Optimization of Latent Thermal Energy Storage with Embedded Metal Foams for Concentrating Solar Power Plants,” Paper No. ES-FuelCell2013-18211, Int Conf Energy Sustainability, 2013.

- A. Verma and R. Pitchumani, “Transient Response of Polymer Electrolyte Fuel Cell to Variations in Operating Parameters and Optimization,” Paper ES-FuelCell2013-18210, 11th Fuel Cell Sci., Engineering & Technology Conf., 2013.

- A. Verma and R. Pitchumani, “Effect of Membrane Properties on the Dynamic Behavior of Polymer Electrolyte Membrane Fuel Cells,” Paper No. ES-FuelCell2013-18209, Fuel Cell Science, Engineering and Technology Conf, 2013.

- A. Verma and R. Pitchumani, “Investigation of Mechanical Behavior of Membrane in Polymer Electrolyte Fuel Cells Subject to Dynamic Changes in Load,” Paper ES-FuelCell2013-18197, Fuel Cell Sci, Eng & Technology Conf, 2013.

- A. Donato and R. Pitchumani, “Stochastic, quantum-based approach to molecular modeling of zeolites,” Paper No. 25598, 247th ACS National Meeting, Dallas, TX, March 16–20, 2014.

- R. Pitchumani, “Challenges and Opportunities for Cost-Competitive Concentrating Solar Power,” Keynote Address, Paper No. JW4A.2, Light, Energy and the Environment Congress, Optical Society of America, Suzhou, China, November 2–5, 2015.

- S. Mishra and R. Pitchumani, “Enabling High Penetration of Solar,” Paper No. 287726, 96th Annual Meeting of the American Meteorological Society, New Orleans, LA, Jan. 10–15, 2016.

- K. Nithyanandam and R. Pitchumani, “Planar Concentrators for Concentrated Solar Thermal Applications,” Paper HT2017-5125, ASME Summer Heat Transfer Conference, 2017.

- K. Nithyanandam, A. Mousavi, R. Stoddard and R. Pitchumani, “Novel Patterned Surfaces for Improved Condenser Performance in Power Plants,” 2018 Crosscutting Research Review Meeting, U.S. Department of Energy NETL, Pittsburgh, PA, April 2018.

- S. Hatte, A. Mousavi, R. Stoddard and R. Pitchumani, “Fabrication and Characterization of Patterned Nonwetting Surfaces for Condenser Applications,” 2019 Crosscutting Research Review Meeting, U.S. Department of Energy NETL, Pittsburgh, PA, April 2019.

- S. Hatte, K. Nithyanandam and R. Pitchumani, “Quantification of Laminar Drag Reduction on Liquid-Infused Structured Non-Wetting Surfaces,” Paper Q23.00007, 72nd Annual Meeting of the APS Division of Fluid Dynamics, Seattle, Washington, November 2019.