Atieh Haghdoost

- Lab Alum

Electrodeposition In Polymeric Micromolds For The Fabrication Of Metallic Microstructures

Electrodeposition is one of the main techniques for fabricating conductive parts with one or two dimensions in the micron size range. This technique is utilized to coat surfaces with protective films of several micrometers thickness or fabricate standalone microstructures. In this process, an electrochemical reaction occurs on the electrode surface by applying an electric voltage, called overpotential. Different electrochemical practices were presented in the literature to obtain kinetic parameters of an electrochemical reaction but most of these practices are hard to implement for the reactions occur on a microelectrode. Toward addressing this issue, the research work presents a combined experimental and analytical method which can more appropriately provide for the kinetic measurement on a microelectrode.

Another issue which occurs for electrodeposition on microscale recessed areas is the deviation of the profile of the deposition front from the substrate shape. Non-uniform deposition front usually obtains for a deposit evolved from a flat substrate with microscale size. Consequently, a subsequent precision grinding process is required to level the surface of the electrodeposited microparts. In order to remove the need for this subsequent process, multiphysics modeling was used to study the effects of the fabrication parameters on the uniformity of the deposit surface and suggest a design strategy.

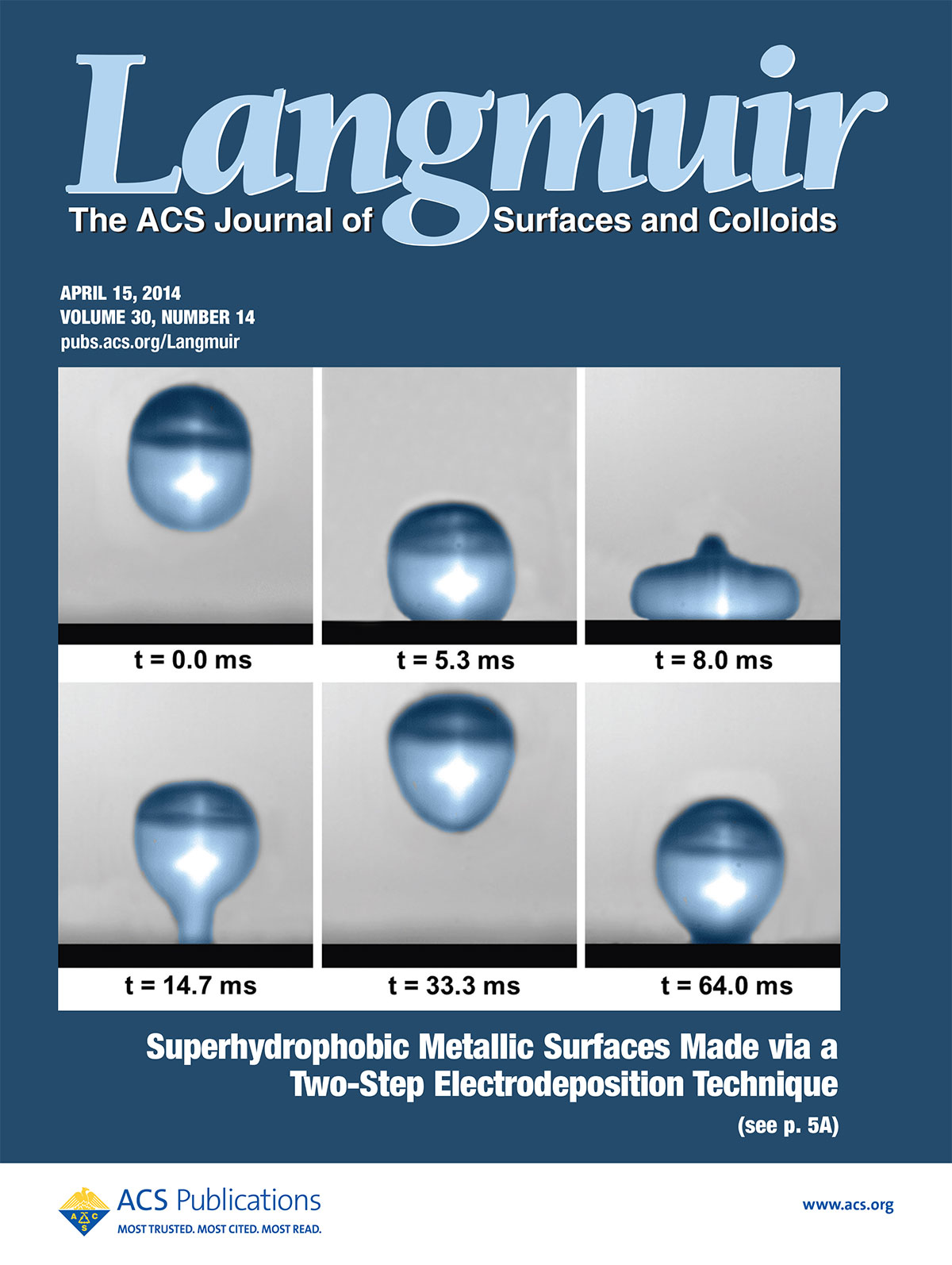

Surface texture of the deposit is another parameter which depends on the fabrication parameters. Several important characteristics of the electrodeposited coating including its wettability depend on the surface texture. Experimental and theoretical studies are conducted to study the effects of overpotential and bath concentration on the surface texture of the copper deposit. As a result of this investigation, a novel two-step electrodeposition technique is developed to fabricate a superhydrophobic copper coating. A study of the effects of the fabrication parameters on the crystalline structure of the deposit shows that nanocrystalline and superplastic materials can be fabricated by electrodeposition if appropriate fabrication parameters are applied.

Publications

- A. Haghdoost, M. Dehkordi , M. Darbandi, M. Shahalami, J. Saien, "Combined Model of Mass-Transfer Coefficients for Clean and Contaminated Liquid-Liquid Systems,” Industrial Engineering Chemical Research, 50(8), 4608-4617, 2011.D.

- Bastani, M. Shahalami, A. Haghdoost, "Genetic Algorithm Approach in Prediction of Mass Transfer and Axial Dispersion Coefficients of Rotating Disc Liquid-Liquid Extraction Contactors", ECCE-6 Conference, Copenhagen, Denmark, September 16-21 2007.

- A. Haghdoost and R. Pitchumani, "Electrodeposition in Polymeric Micromolds for the Fabrication of Metallic Microstructures," Paper No. IMECE2010-37751, Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Vancouver, British Columbia, Canada, November 12-18, 2010, 9 pp., 2010.

- A. Haghdoost and R. Pitchumani, “Super-Repellancy via Controlled Topography of Particle-Coated Surfaces,” in Proceedings of the 36th Annual Meeting of the Adhesion Society, Inc., March 3–6, 2013, Daytona Beach, FL.

- A. Haghdoost and R. Pitchumani, “Numerical Analysis of Electrodeposition in Microcavities,” Electrochimica Acta, 56(24), 8260–8271, 2011.

- A. Haghdoost and R. Pitchumani, “Electrodeposition in Micromolds with a Microscreen Base,” Acta Materialia, 61(20), 7568–7581, 2013.

- A. Haghdoost and R. Pitchumani, "Fabrication of Superhydrophobic Surfaces via a Two-Step Electrodeposition Technique", Langmuir, 30(14), 4183–4191, 2014. Cover Feature Article.

Sponsor