Rahul Jain

- Lab Alum

- M.S. Mechanical Engineering (2017)

Biography

Rahul Jain received a Master of Science degree from the Advanced Materials and Technologies Laboratory at Virginia Tech. He received his Bachelor’s degree in Mechanical Engineering from the Indian Institute of Technology, Jodhpur in 2012. His primary research interests are in fluid/thermal science, superhydrophobic coatings, fractal modeling, and turbomachinery. Upon completion of his Master’s degree, Rahul joined Praxair, Inc., starting August 2017.

Research Projects

Fabrication of Durable Superhydrophobic Surfaces via Electrodeposition and Etching

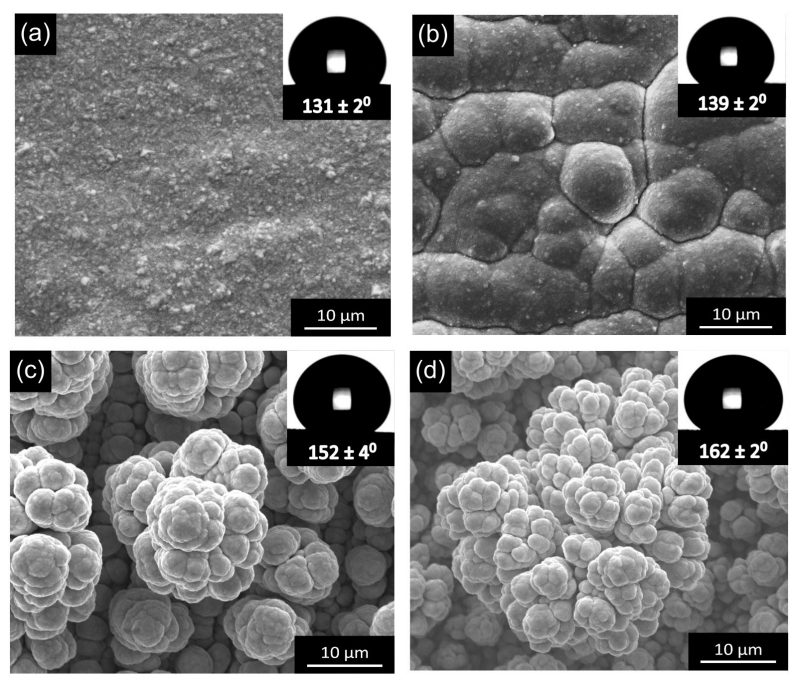

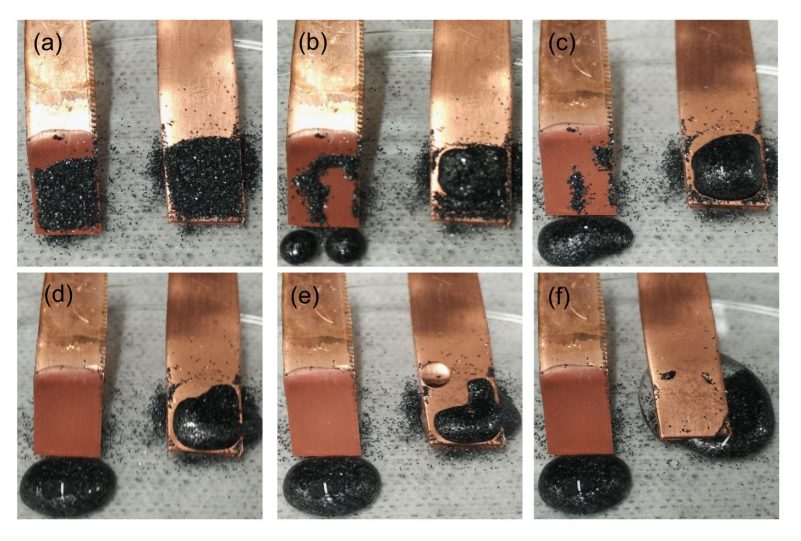

Superhydrophobic surfaces have myriad industrial applications, yet their practical utilization has been limited by their poor mechanical durability and longevity. We present a low cost, facile process to develop superhydrophobic copper based coatings via electrodeposition route, that addresses this limitation. Through electrodeposition, a stable, multiscale, cauliflower shaped fractal morphology was obtained and upon modification by stearic acid, the prepared coatings show extreme water repellency with contact angle of 162 ± 2o and roll-off angle of about 3o. Systematic studies are presented on coatings fabricated under different processing conditions to demonstrate good durability, mechanical and underwater stability, corrosion resistance and self-cleaning effect. The study also presents an approach for rejuvenation of slippery superhydrophobic nature (roll-off angle < 10o) on the surfaces after long term water immersion.

Demonstration of exceptional superhydrophobicity

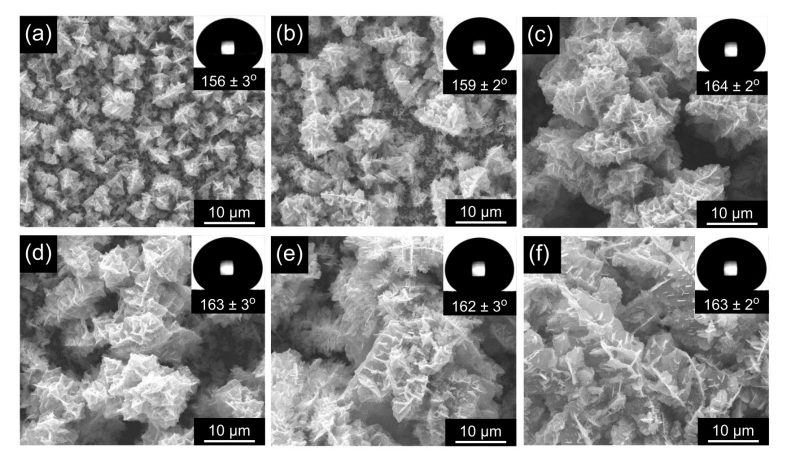

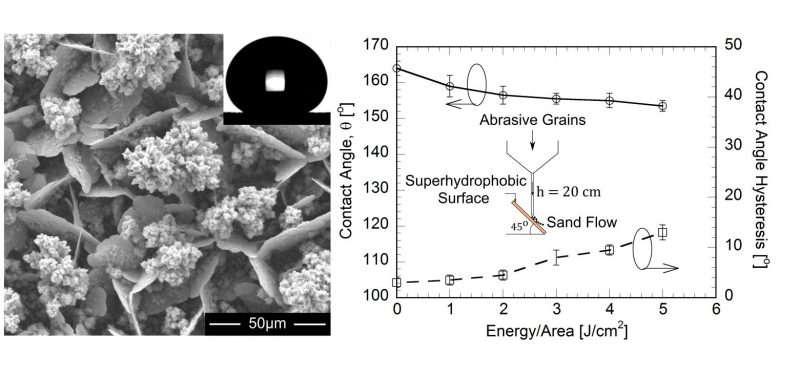

The process can be scaled to larger, durable coatings with controllable wettability for diverse applications. For example, zinc coatings are widely used in the surface finishing industry to improve the corrosion resistance of steel structures. Generally, an additional decorative hexavalent chromium layer is deposited for corrosion protection, which leads to carcinogenic chrome emissions. In this work, we present an electrodeposition based approach to fabricate superhydrophobic zinc coatings, that eliminates the need for the additional chrome layer while enhancing the corrosion resistance of the zinc coating by about one order of magnitude. Through electrodeposition in a highly conductive electrolyte, a multiscale needle and branch-shaped fractal morphology was obtained in the coatings, which were treated with stearic acid to obtain extreme water repellency in the prepared coatings, with contact angle of more than 160 and roll off angle of about 4–7. Detailed microstructural and mechanical characterization studies are presented on the fabricated coatings under different processing conditions to demonstrate their durability, stability, longevity, and corrosion resistance.

Our patented process is scalable to a variety of metals.

Fractal Model for Wettability of Rough Surfaces

This research presents a fractal model to describe wettability on multiscale randomly rough surfaces. Hydrophobic or superhydrophobic surfaces produced using processes such as electrodeposition and etching lead to the creation of random roughness at multiple length scales on the surface. This paper considers the description of such surfaces with a fractal asperity model based on the Weierstrass-Mandelbrot (W-M) function, where the fractal parameters are uniquely determined from a power spectrum of the surface. Using this description, a model is presented to evaluate the apparent contact angle in the different wetting regimes. The model is predictive in that it does not use any empirical or correlatory fitting of parameters to experimental data. Experimental validation of the model predictions is presented on various hydrophobic and superhydrophobic surfaces generated on several materials under different processing conditions. The contact angle is found be strongly dependent on the range of asperity length scale and weakly dependent of the fractal dimension for a surface with stable Cassie state. Based on the fractal description, desired surface roughness characteristics for generating superhydrophobicity on a particular substrate are also derived.

Multiscale, Fractal Textured Solar Selective Coatings

Photothermal conversion efficiency depends significantly on the selectivity of the thermal receiver surface through which a heat transfer fluid flows in a concentrated solar power system. This research presents studies on novel multiscale, fractal textured solar selective coatings for solar thermal applications. The fractal surfaces are fabricated integrally on the substrate material using electrodeposition. The coatings are described in terms of fractal parameters that are uniquely determined from surface measurements, and the optical properties of the coatings are experimentally characterized in detail in terms of the fractal parameters. The effects of heat treatment on the optical properties of coatings over a range of fractal parameters are also described. The study is presented considering coatings on copper to demonstrate that fractal texturing of the surface provides a nearly three-fold performance improvement compared to coatings with no texturing or heat treatment. The findings equally apply to other materials used in higher temperature solar thermal applications.

Publications

- R. Jain and R. Pitchumani, “Facile Fabrication of a Robust Copper-based Superhydrophobic Surface via Electrodeposition,” Langmuir, 34(10), 3159–3169, 2018, Cover Feature Article.

- R. Jain and R. Pitchumani, “Fabrication and Characterization of Durable Zinc Based Superhydrophobic Coatings,” Surface and Coatings Technology, 337, 223–231, 2018.

- R. Jain and R. Pitchumani, “Fractal Model for Wettability of Rough Surfaces,” Langmuir, 33(28), 7181–7190, 2017.

- R. Jain and R. Pitchumani, “Fabrication and Characterization of Multiscale, Fractal Textured Solar Selective Coatings,” Solar Energy Materials and Solar Cells, 172C, 213–219, 2017.

- R. Jain, “Investigations on Multiscale Fractal-textured Superhydrophobic and Solar Selective Coatings,” M.S. Thesis, Advanced Materials and Technologies Laboratory, Virginia Tech, 2017.