Ryan Stoddard

Biography

A native of Cross City, Florida, Commander Ryan Stoddard graduated from the United States Naval Academy and was commissioned as a naval officer in 1998. After earning his pilot wings in 2001, he served for 22 years in various shore and sea duty billets including command of Fleet Air Reconnaissance Squadron FOUR. Ryan has flown five different airframes, accumulating over 2500 flight-hours and served as an aircraft carrier Assistant Navigator. His most recent tour was as the Junior Military Assistant to the Secretary of Defense and today he serves as the Executive Officer of the Virginia Tech NROTC unit. Throughout his Navy career, Ryan has actively furthered his education outside of his official responsibilities, earning an MS in Mechanical Engineering from Georgia Tech and an EMBA from the Naval Postgraduate School. Ryan’s PhD research in the AMTL is focused on phase change heat and mass transfer on non-wetting surfaces.

Research Projects

Ryan’s study of non-wetting surfaces includes phase change heat transfer on superhydrophobic surfaces and liquid-infused surfaces. Ryan’s research is focused on industrial application of non-wetting surfaces toward improved condensation heat transfer under power plant condenser conditions, anti-icing, and atmospheric water generation, with a focus on durability and real-world applicability. His research bears applications to numerous industrial and environmental sustainability systems. Specific research contributions are as follows.

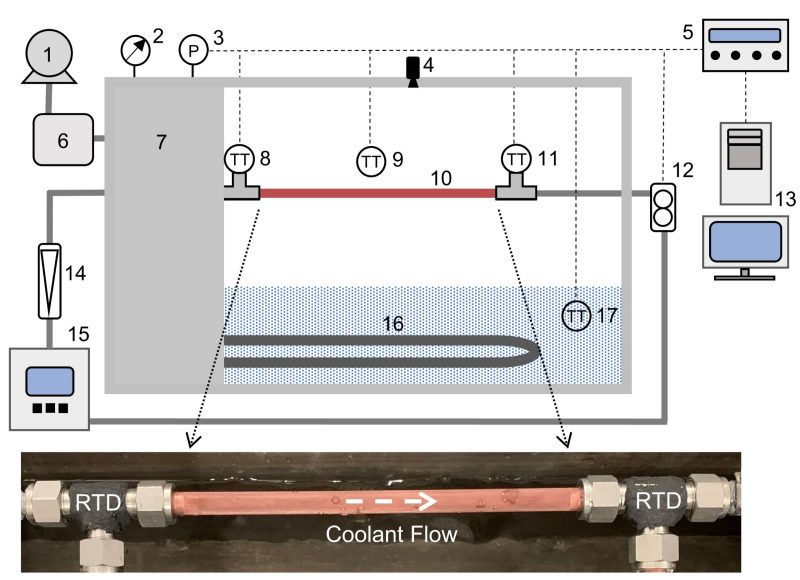

A Study of Condensation Heat Transfer on Superhydrophobic Surfaces in Power Plant Condenser Conditions

Condensation of steam is critical in multiple industrial applications. Drop-wise condensation can produce heat transfer coefficients that are an order of magnitude larger than those achieved from film-wise condensation. Classic studies in the literature focused on promoting sustained drop-wise condensation using noble metals or surface treatments of an otherwise smooth condensing surface. Recent studies have found that superhydrophobic surfaces can produce sustained drop-wise condensation. These studies focus on the morphology of the microscale or nanoscale surfaces as the key to superhydrophobicity and heat transfer performance, while ignoring the importance of the functionalizing agent applied to induce superhydrophobicity. In this paper, copper tubes are modified to produce four different surface finishes, each with a distinct surface morphology and roughness profile. Five different functionalizing agents are tested on each surface finish to determine degree of hydrophobicity and heat transfer performance. Both surface finish and functionalizing agent are addressed equally for their role in improving both qualities, providing a blended approach of the classic, drop-wise condensation promotion studies and the recent, superhydrophobicity studies. Functionalizing agents that produce positive results on copper are also tested for heat durability and compatibility with other, commonly used condenser metals. Results are presented in terms of both condensation heat transfer coefficients and a new, contextual heat transfer effectiveness term. Heat transfer effectiveness values presented address the condensing surface as a part of the heat transfer system to which it is attached, thereby appropriately bounding possible heat transfer performance improvements. This approach allows a direct, percentage-based comparison of improvements as they would apply to a functioning condenser.

Above: Condensation on a smooth surface.

Above: Enhanced condensation on our non-wetting surface.

Publications

- S. Hatte, R. Stoddard, and R. Pitchumani, “Novel Nonwetting Surfaces for Enhanced Condenser Performance in Thermal Power Plants,” Thermopedia, Begell House, Inc., 2024.

- S. Hatte, R. Stoddard and R. Pitchumani, “Novel Solid-Infused Durable Nonwetting Surfaces for Sustained Condensation Heat Transfer Enhancement,” Applied Thermal Engineering, 219, 119458, 2023.

- S. Hatte, R. Stoddard and R. Pitchumani, “Generalized Analysis of Dynamic Flow Fouling on Heat Transfer Surfaces,” International Journal of Heat and Mass Transfer, 188, 122573, 2022.

- R. Stoddard, K. Nithyanandam and R. Pitchumani, “Fabrication and Durability Characterization of Superhydrophobic and Lubricant-Infused Surfaces,” Journal of Colloid and Interface Science, 608, 662–672, 2022.

- R. Stoddard, K. Nithyanandam and R. Pitchumani, “Steam Condensation Heat Transfer on Lubricant Infused Surfaces,” Invited Article, iScience, 24(4), 102336, 2021.

- R.M. Stoddard, A.M. Blasick, S.M. Ghiaasiaan, S.I. Abdel-Khalik, S.M. Jeter, and M.F. Dowling, “Onset of Flow Instability and Critical Heat Flux in Thin Horizontal Annuli.” Experimental Thermal and Fluid Science, 26, 1-14, 2002.

- N.V. Aunapu, R.J. Volino, K.A. Flack, and R.M. Stoddard, “Secondary Flow Measurements in a Turbine Passage with Endwall Flow Modification,” Journal of Turbomachinery, 122(4), 651-658, 2000.

Sponsors